Flow Formed Wheels

This is a relatively new method, that’s a sort of hybrid between forged and cast wheels (although it’s not to be confused with forged wheels as the process is entirely different.)

Flow formed wheels are a step up in load bearing capacity (and strength) and in a lighter weight from cast wheels.

Let’s take a look at why.

The Wheel “Flow Form” Process:

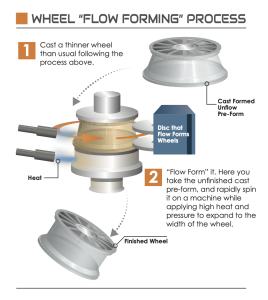

- Cast a thinner wheel than usual following the process above.

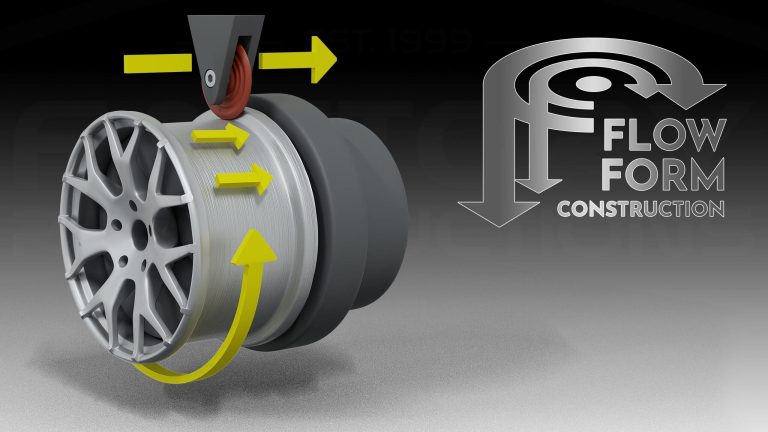

- “Flow Form” it. Here you take the unfinished cast wheel, and rapidly spin it on a machine while applying high heat and pressure to expand the width of the wheel.

The first main benefit here is a lighter wheel because less material is used. Different flow forming techniques and manufacturing processes result in a wheel that’s anywhere from 15% to 25% lighter than a cast wheel.

The second is increased strength. The flow forming process both compresses and stretches the metal, changing its composition and increasing its tensile strength. This leads to increased shock resistance and a higher load capacity.

Who Would Benefit Most From a Flow Formed Wheel?

Flow formed wheels are a great option for those who want something lighter and more durable than a cast wheel. On the track, for example, less weight leads to less rotating mass, a benefit for both greater acceleration and breaking efficiency.

Applications for flow formed wheels include;

- Everyday driving

- Casual racers in smaller cars

- Performance drivers who don’t require as heavy a load capacity.

Of course, you can expect a flow formed wheel to be more expensive than a cast wheel because of the technology and extended process used in its creation.

Flow formed wheels brands

For quality assurance and safety on the road, it’s important to research carefully before choosing a well-respected manufacturer, as the source and composition of their alloy, along with the unique techniques they use for flow forming all make a difference in the final product. Five well respected flow forming manufacturing companies to start with include:

Konig – One of the most recognizable aftermarket wheel brands around, Konig has been making quality and trust wheels for almost 40 years. Car enthusiasts and global OEM brands alike know them for their high standards in wheel manufacturing.

Enkei – A Japanese Corporation established in 1950, they are known for developing some of the lightest performance wheels on the market. They all the largest Japanese car manufacturers and General Motors in the OEM market, they also supply the consumer automotive aftermarket, as well as the Formula 1 McLaren Honda team since 1995.

BBS – First introducing their aftermarket flow-formed wheel back in 1996, BBS is world renown for impeccable quality. BBS supplies cast flow-formed wheels for many high performance OEM manufacturers including: BMW, Audi, Mercedes and Porsche. Other factory racing programs such as BMW, Ferrari and Ford have selected a BBS cast flow-formed product specifically for track use.

TSW – Founded by a Formula 1 driver, TSW has produced performance driven aftermarket alloy wheels since 1967. They’re known as much for their quality, precision engineering, and advanced materials as they are their impeccable design. Their take on flow-formed wheels, is a process they call “ROTARY FORGED™ WHEELS”

CWS – Custom Wheel Solutions has provided all types of casting and flow forming wheels under white label programs for more than three decades. Having built a number of factories all over the world, CWS management has “hands on” experience in designing, constructing and managing complete turnkey forged, cast and flow forming manufacturing facilities. They supply the automotive aftermarket, the RV market, military and automotive OEM’s (original equipment manufacturers, FORD, GM FCA, Toyota, etc.) as well as producing wheels for many racing venues.

Other companies that offer flow forged wheels include Vossen, Ferrada, Avant-Gardenia, and Stance.

The first main benefit here is a lighter wheel because less material is used. Different flow forming techniques and manufacturing processes result in a wheel that’s anywhere from 15% to 25% lighter than a cast wheel.

The first main benefit here is a lighter wheel because less material is used. Different flow forming techniques and manufacturing processes result in a wheel that’s anywhere from 15% to 25% lighter than a cast wheel.