The wheel, right after being one of the most important inventions of all times, has also been among the crucial parts of every vehicle. The construction of a car wheel is not usually considered to be very complicated when compared to other car systems and parts. We all are aware that a wheel includes rims and car tyres.

What some drivers do not realise, however, is the importance of certain wheel parameters. Understanding these will make finding and purchasing new wheels much easier. Read on to find out what the most important facets of wheel construction are and why they matter.

There are four basic aspects related to the construction and parts of a car wheel motorists should be aware of. They include:

- Wheel size

- Bolt pattern

- Wheel offset

- Centre bore

Let’s take a closer look at these parameters and, breaking them down, explain how car wheels work.

Wheel size

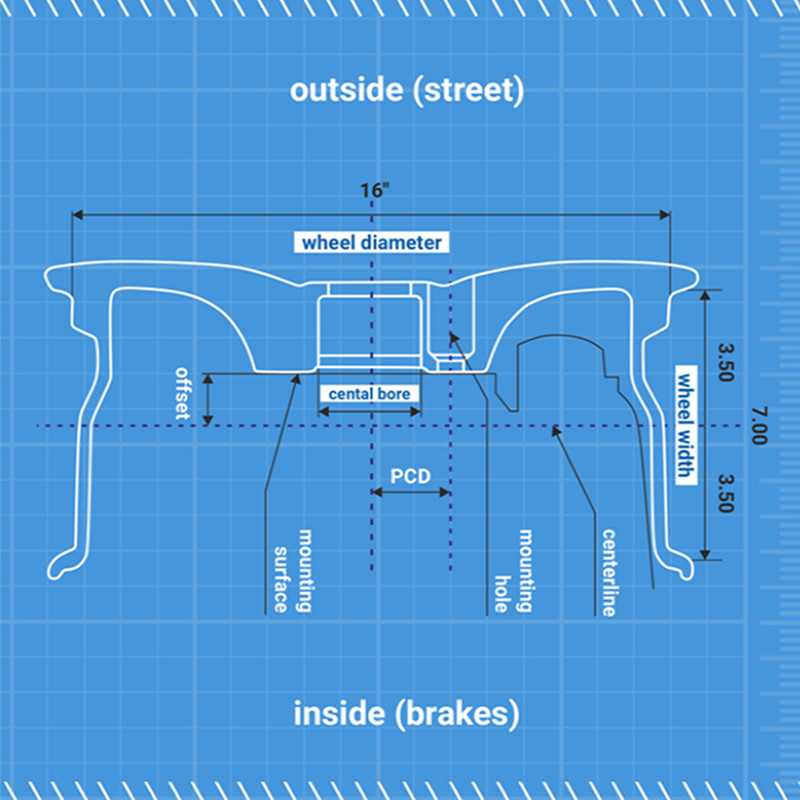

The wheel size consists of two other parameters: the width and the diameter. The width refers to the distance between one and the other bead seat. The diameter is the distance between the two sides of the wheel measured through the central point of the wheel.

Wheel size is expressed in inches. An example wheel size, then, could be 6.5×15. In this case, the width of the wheel is 6.5 inches and the diameter is 15 inches. The wheels of standard road cars are typically between 14 inch and 19 inch in diameter.

Wheel bolt pattern

Car wheels have bolt holes which should match the vehicle’s studs on the mounting hubs. They always form a circle. The bolt pattern refers to the positioning of these mounting holes.

It appears in a similar code to the wheel size. This time, the first number refers to how many mounting holes there are and the second number, expressed in mm, then gives the width of this ‘bolt circle’.

For example, a 5×110 bolt pattern has 5 bolt holes, forming a circle with a 110 mm diameter.

The bolt pattern must match the pattern on the axle hub. This is important because different car hubs have different bolt patterns and the bolt pattern determines which car model a given wheel rim can be installed on. So you should always remember to use the wheels with a matching number of holes and diameter.

Wheel offset

The offset value describes the distance from a wheel’s plane of symmetry to the mounting plane (where the rim and the hub connect). Wheel offset indicates how deep in the wheel the housing is located. The larger the offset, the deeper the positioning of the wheel is. This value, like wheel bolt pattern, is expressed in millimetres.

Offset can be positive or negative. Positive means that the hub-mounting surface is closer to the outside edge of the wheel, zero offset is when mounting surface is in line with the centerline, while in the case of a negative offset, the mounting surface is closer to the inside edge of the wheel.

Offset can be a little complicated to comprehend but it’s worth knowing that the choice of wheels with a given offset also depends on the construction of the car’s wheel housing, driver preferences, the chosen wheel and tyre size etc.

For example, a car might be able to take both 6.5×15 5×112 offset 35 and 6.5×15 5×112 offset 40, but the first tyre (with an offset of 35) will give the effect of a larger width.

Wheel centre bore

Car wheels have a hole in the back that centers the wheel over the mounting hub of the car. The centre bore refers to the size of that hole.

The centre bore of some factory wheels matches exactly with the hub to keep the wheel centered reducing vibration. Fitting snugly against the hub, the wheel is centred to the car while reducing the job of the lug nuts. Wheels that have the correct centre bore to the vehicle where they are mounted are called hub-centric wheels. Lug-centric wheels, in turn, are those that have a gap between the center hole of the wheel and the hub. In this case, the job of centering is done by the properly fitted lug nuts.

If you are considering aftermarket wheels, it is worth remembering that the centre bore on such must be equal to or larger than that of the hub, otherwise the wheel cannot be mounted on the car.

In general, however, the centre bore is not crucial in determining the wheel size or finding new wheels so the truth is that you don’t have to worry so much about it as a regular car user.

If you know what wheel size, bolt pattern and wheel offset are and why they matter in a vehicle, you will already have enough technical understanding to choose the right wheels for your car.