Introduction to Forged Wheels

What Are Forged Wheels?

A forged wheel is manufactured from a single piece of metal by applying both heat and pressure. This method starts with a solid billet of metal, usually aluminum, which is then shaped into a wheel under extreme pressure. The outcome is a wheel with a dense grain structure, significantly enhancing its strength and reducing its weight compared to traditional cast wheels. This distinctive manufacturing process distinguishes forged wheels in terms of their durability and performance.

History and Evolution of Forged Wheels

The concept of forged wheels first gained popularity in aerospace and military applications due to the need for lightweight yet strong components. Over time, this technology found its way into high-performance and racing vehicles, where the benefits of reduced weight and enhanced strength could be fully leveraged. Today, forged wheels are increasingly common in commercial and luxury vehicles, blending the demands of modern driving with cutting-edge manufacturing techniques.

How Are Forged Wheels Made?

The production of a forged wheel begins with a solid piece of aluminum billet. This is heated to a precise temperature and then subjected to massive pressures, which forces the metal into the shape of a wheel. This forging process realigns the metal’s grain structure, making it denser and stronger. The wheel is then machined to its final dimensions, ensuring precise tolerances are met. This meticulous process results in a high-performance wheel that is durable and reliable.

Benefits of Forged Wheels

Unparalleled Durability

One of the standout benefits of a forged wheel is its exceptional durability.

Increased Strength and Endurance

The forging process results in a wheel that is much stronger compared to a conventional cast wheel. This enhanced strength allows forged wheels to better endure impacts, thereby decreasing the chances of cracking or deforming under pressure. This durability is especially advantageous for drivers who frequently drive on rough roads or encounter potholes.

Resistance to Bending and Cracking

Due to the integrity of the grain structure, forged wheels are inherently more resistant to bending and cracking. This resilience ensures a longer lifespan for the wheel, making it a wise investment for those who prioritize long-term reliability and safety.

Enhanced Performance

Forged wheels aren’t just about durability; they also significantly enhance the vehicle’s performance.

Improved Handling and Acceleration

The reduced weight of forged wheels directly translates to improved handling and acceleration. A lighter wheel helps reduce the unsprung weight of the vehicle, leading to better responsiveness and a tighter feel on the road. This results in sharper turns and a more agile driving experience.

Fuel Efficiency Gains

Due to their reduced weight, forged wheels can also enhance fuel efficiency. Lowering the vehicle’s total weight means that the engine has less strain to move the car, potentially leading to improved fuel economy over time.

Design Aspects of Forged Wheels

Aesthetic Customization Options

Finish Types (Glossy, Matte, Polished)

When it comes to customization, forged wheels provide numerous finish options. Whether you prefer a glossy sheen, a sophisticated matte effect, or a polished finish that gleams, there’s a style to match every personal taste and vehicle aesthetic. These finishes not only enhance the look of the wheel but also add a layer of protection against the elements.

Color Choices and Combinations

The ability to choose from an array of colors and combinations further sets forged wheels apart. From classic silver and black to more vibrant hues like red or blue, there are virtually limitless options for expressing individuality and complementing the vehicle’s appearance.

Engineering Precision

The design of a forged wheel is not solely about aesthetics; it also involves meticulous engineering.

Lightweight Design Benefits

The forging process naturally results in a lighter wheel, which brings several performance benefits. The reduction in unsprung weight improves the vehicle’s agility and responsiveness, making for a more dynamic driving experience. Lighter wheels also place less strain on suspension components, contributing to a smoother ride and prolonged vehicle health.

Heat Dissipation Features

Another notable engineering feature of forged wheels is their superior heat dissipation. The dense grain structure and precise machining allow for better heat management, which is particularly important in high-performance and racing applications. Efficient heat dissipation helps maintain optimal tire performance and reduces the risk of heat-induced damage.

In conclusion, forged wheels combine the best of durability, performance, and aesthetics, making them a versatile and valuable option for drivers seeking to enhance their vehicle’s overall capabilities. Whether you’re drawn by their strength, their contribution to fuel efficiency, or their customizable design features, forged wheels offer a compelling choice for those dedicated to both performance and style.

Choosing the Right Forged Wheels for Your Vehicle

The Vesteon Wheel Company is a big name in the auto business, and they make and sell alloy wheels for cars. Vesteon has a wide selection of alloy wheels to suit different customer tastes and car types. They put a lot of emphasis on quality and new ideas. Advanced manufacturing techniques and cutting-edge tools are used to carefully plan and make these wheels, which guarantees that they will work well and last a long time.

Vesteon Wheel Company is proud of its wide range of products, which includes metal wheels in many shapes, sizes, and finishes. Vesteon has designs that are both sleek and modern and traditional and timeless, so there is something for everyone. Additionally, their metal wheels are renowned for being very strong while also being very light. This not only makes cars look better but also makes them more fuel-efficient and easier to steer.You can choose from 1-Piece, 2-Piece, and 3-Piece cast wheels in their large selection.Vesteon Wheel Company is committed to providing excellence and is a trusted choice for both car enthusiasts and professionals in the industry. It stands out from rivals by focusing on quality, customer satisfaction, and a wide range of products.

Factors to Consider Before Purchase

Vehicle Compatibility

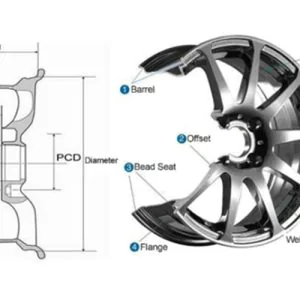

Choosing the appropriate forged wheel for your vehicle is essential to ensure compatibility. Wheels that do not match can negatively impact both performance and safety. It is important to verify the bolt pattern, offset, and size specifications for your particular vehicle model.

Driving Needs and Preferences

Another key consideration is your driving needs and preferences. If you frequently drive in city conditions, a lighter forged wheel can improve fuel efficiency and enhance handling. For off-road or rough road conditions, you might prioritize strength and resistance to impacts. Additionally, your driving style—whether you prefer a sportier feel or a comfortable ride—should influence your choice. Matching the characteristics of the wheel to your driving habits ensures optimal performance and durability.

Top Brands in the Market

While we won’t dive into specific names, it’s worth noting that several manufacturers are renowned for their high-quality forged wheels. These brands have built their reputations on precise engineering, superior materials, and rigorous quality control. When choosing a wheel, research the technical specifications and reviews from other users. This can give you insight into the wheel’s real-world performance and reliability.

Maintenance Tips for Forged Wheels

Regular Cleaning and Care

Proper maintenance extends the life and retains the aesthetics of your forged wheel. Regular cleaning is essential to prevent dirt and brake dust from accumulating and causing corrosion. Use a gentle cleaner specifically designed for wheels and a soft brush to clean the intricate parts without damaging the surface.

Recommended Cleaning Products

Choosing the appropriate cleaning products for your forged wheel is essential. Pick pH-balanced wheel cleaners and steer clear of harsh chemicals that might harm the finish. Wheel wax or sealants can offer an extra layer of defense against environmental pollutants. Always select products that are suitable for the type of finish on your wheels.

Inspecting for Wear and Tear

Regular inspections help catch early signs of wear and tear on your forged wheel. Look for any cracks, bends, or unusual wear patterns, which could indicate underlying issues. Regularly checking the wheels’ condition ensures they remain safe and reliable. If you notice any damage, it’s best to consult a professional to assess whether repair or replacement is necessary.

Overcoming Common Misconceptions About Forged Wheels

Comparing Forged Wheels to Cast Wheels

There are several common misconceptions when comparing forged wheels to cast wheels. One significant difference lies in the manufacturing process. Forged wheels are pressed from a solid piece of metal, enhancing their strength and lightness. In contrast, cast wheels are made by pouring molten metal into a mold, which can introduce structural weaknesses. These differences affect the performance, durability, and overall quality of the wheels.

Debunking Myths Around Cost

Many individuals believe that forged wheels are excessively expensive. While the initial cost is indeed higher than that of cast wheels, it’s important to consider their long-term value. The superior durability and performance of forged wheels can result in savings on repairs and replacements over time. Moreover, the enhanced fuel efficiency and driving experience they offer add to their overall value.

Addressing Longevity Concerns

Some myths suggest that forged wheels have a shorter lifespan than other wheels, but this is unfounded. Thanks to their robust construction and superior materials, forged wheels often outlast their cast counterparts. Their resistance to bending, cracking, and other forms of wear means they can endure the rigors of daily driving and harsh conditions, offering long-term reliability and peace of mind.

By considering compatibility, understanding your driving needs, and maintaining these wheels properly, you can maximize the benefits of your forged wheel investment. Dispelling common misconceptions further highlights why these wheels are a smart choice for those who value performance, safety, and style.