Over time, alloy wheels are bound to experience damage, whether it’s light scratches or kerb damage. Although your first instinct is probably to call a mechanic or head to a car repair center, these are fairly costly options. But with a bit of DIY knowledge, you can repair scratches, kerb damage, bends, and corrosion at a fraction of the price that many auto dealers charge!

Method1

Filling Scratches and Kerb Damage

1

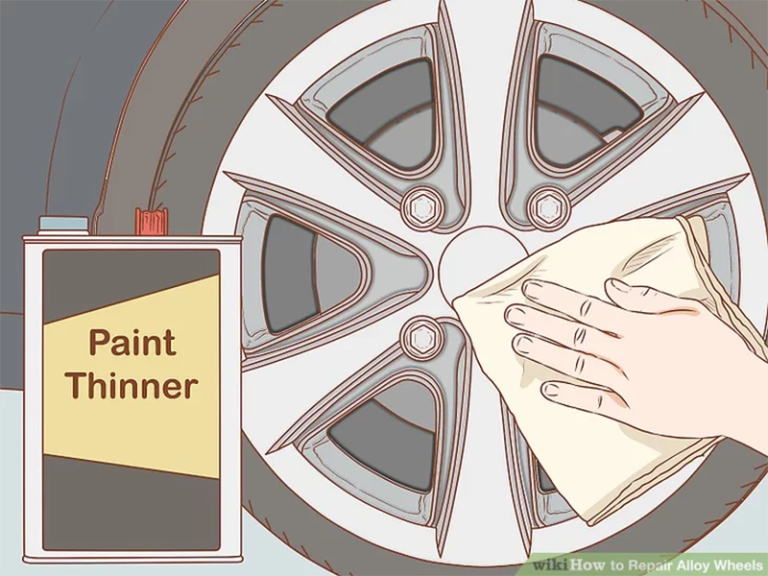

Clean the area surrounding the damage with paint thinner. Purchase a non-acidic cleaner and apply it to a clean microfiber cloth or soft-bristled detailing brush. Scrub the damaged areas of the wheels with your cloth or brush by moving it in small circles. For areas with lots of buildup, be generous with the cleaner and be sure they get a thorough scrub.

- Focus your efforts on the most damaged areas.

- Be sure to get all of the wax and polish from the area around the damage. Failing to do this will hinder the repair process.

- Wipe the area dry with a soft cloth when you’re done.

2

Sand the damaged area with 240-grit sandpaper. Wrap your sandpaper over a small piece of wood about 2 by 4 inches (5.1 by 10.2 cm)—anything that can fit comfortably in your hand. Fold the sandpaper over the block firmly so it sits completely flat against it. Hold the sand block so that the edges are under your palm and your thumb and other fingers grip the sides. Apply pressure to the flat top part of the block with your index finger.

- Continue sanding the alloy wheel until the surface is as smooth as possible.

3

Wipe some spot putty onto the scratched region. Squeeze a coin-sized dab of putty onto a 2 inch (5.1 cm) putty knife. Drag the knife at a 45-degree angle over the scratched area and press it down until it’s as level with the alloy wheel as possible. The spot putty will start to set within a few minutes, so work as fast as possible.

- Always work in a cool, well-ventilated area.

- Avoid cold, damp areas—the putty will not dry properly.

- Purchase spot putty from a department store or in alloy wheel repair kits available from online suppliers.

4

Sand the putty with 400-grit sandpaper until it’s flush. After the putty is dry, place 400-grit sandpaper over your sanding block and sand the damaged areas a final time. Continue sanding until the putty looks level with the rest of the rim.

- If you don’t have 400-grit sandpaper, use the finest (also known as the highest grit) sandpaper that you have.

Method2

Fixing Bends

1

Apply lube around the circumference of the rim. Before you pry off your rim, lubricate its outside edge where it meets the wheel. If your lubricant is in a spray can, hold it about 1 inch (2.5 cm) over the circumference and apply it. For jar lubricants, apply it to the same area using a cloth.

- Purchase lubricant from auto parts stores or online suppliers.

2

Remove the alloy wheel rim from the tire. Place the tire onto a flat surface with the rim facing upward. Sit on the edge of the wheel and insert a tire iron between the wheel and the rim at the farthest location from you with the curved side facing down. With the tire iron facing upward, pull backward until the rim pops out from the wheel.

- Continue this process around the circumference of the rim until it’s completely loose from the wheel.

3

Place your alloy wheel rim onto the wheel on a stable flat surface. Find a garage with a concrete floor for the best results. Place a piece of cardboard down and then place your tire on top of it. To hold the alloy wheel in place, place it on top of the tire and push it down so it inserts slightly into the center hole.

- Be sure there isn’t any gasoline or flammable products in the proximity.

4

Heat the bent area to 302 °F (150 °C) from the inside with a blow torch. Hold the digital thermometer about 1 foot (0.30 m) from the outside edge of the alloy. From the inside, apply the blow torch at a 45-degree angle, moving side to side over the bend. Continue this motion until the alloy wheel reads 302 °F (150 °C) on the thermometer.

- Keep the blow torch about 1 inch (2.5 cm) from the wheel.

5

Find a piece of wood that fits into your dent. Your best bet is a curved sanding block from an office supply store or online supplier. Select a piece of wood with a curve as close as possible to the dent, but don’t stress if it doesn’t fit perfectly.

- If you use a sanding block, stick to wooden products. If all you can find is rubber, that’s fine—it just might not be as effective.

6

Hit the dent with your wood and a heavy rubber mallet. Now that the alloy is heated and malleable, you can bend it back into shape. Place the curved piece of wood or rubber into the dent and attack it from the side with a heavy rubber mallet. Swing vertically and with enough force to change the shape of the metal.

- After the alloy is not changing shape anymore, you can remove the wood piece and attack it straight-on with the hammer. However, this technique is more likely to cause wheel damage, so do so at your own risk.

- Avoid using a metal hammer or you risk breaking the alloy wheel.

Method3

Removing Corrosion

1

Wash and polish the alloy wheel with water. Use a hose to spray down your alloy wheel thoroughly. Focus your efforts on the area between and around the spokes, which is where dust and dirt have a tendency to accumulate. Be sure that all of the corroded areas are thoroughly cleaned.

- Attach a fireman’s nozzle to your hose to improve its stream.

2

Dry the wheel using a microfiber cloth. Firmly scrub the surface of the wheel until it is completely dry. Always use a soft microfiber cloth to avoid damaging the finish of your wheel, and avoid air-drying your wheels to prevent spots from forming.[12]

- Keep your wheel-drying cloths separate from your others to prevent dust and dirt from accumulating on them.

3

Remove oxidation using an aluminum polish pre-cleaner. Spray the cleaner onto your wheels and focus on the corroded areas. Afterward, let your wheels sit for about 10 minutes. Once the pre-cleaner has had enough time to set in, brush the corroded areas with a wheel brush.

- Wipe in circular motions and focus your efforts on the areas with the highest amount of corrosion.

4

Scrub the roughest corrosion spots using 40-grit to 60-grit sandpaper. Start by soaking the corroded portions with water. Afterward, rub your sand paper side to side over them by hand while applying pressure. Continue this until you notice the pitting—the small holes created by localized corrosion—start to fade.

- Apply as much pressure as possible toward the wheel.

5

Switch to higher grit sandpaper and continue sanding. Once the pitting starts to fade, switch to 240-grit sandpaper. Continue sanding side to side until you don’t notice a change in the visibility of the pitting. Switch to 400-grit sandpaper and continue sanding until the pitting is barely visible or not visible at all.

- Don’t worry about applying as much pressure when using finer sandpaper.

6

Apply wheel wax to prevent further oxidation. Dip your foam applicator into wheel wax and rub it directly onto your alloy wheels. Be sure to apply a generous amount and spread it evenly over the entire alloy surface. Afterward, remove it with a soft cotton towel.

- Always use clean cotton towels to avoid contaminating your alloy wheel with dirt.

- Wax will help protect your wheels from wearing down and keep them cleaner.