In our daily lives, “tires” can be seen everywhere, from airplanes to ships; From small strollers to toys. In cars, tires are an indispensable component. As a car owner, it is important to understand and be familiar with the specifications, patterns, classification, and maintenance of tires. Below, the author will introduce each of them one by one.

Tire specification number

The international standard tire code represents the percentage of cross-sectional height and flatness ratio in millimeters, followed by the tire type code, rim diameter, load index, and allowable speed code. For example, in 175/70R 14 77H, 175 represents a tire width of 175MM, 70 represents a flat ratio of 70% of the tire section, that is, the section height is 70% of the width, the rim diameter is 14 inches, the load index is 77, and the allowable speed is H-class.

Common methods for representing tire specifications

Level: Level refers to the nominal number of ply layers within the rubber layer of a tire, which is not completely consistent with the actual number of ply layers and is an important indicator of tire strength. The hierarchy is marked in Chinese, such as 12 levels; Use English symbols, such as 14P R “refers to the 14 layer pole.

Load and air pressure: Generally, the maximum load and corresponding air pressure are indicated, and the load is measured in kilograms. The air pressure is the tire pressure, measured in kilopascals.

Rim size: Refers to the size of the rim used in conjunction with the tire. Easy to use in practice, such as “Standard Rim 5.00F”.

Balance mark: Made of colored rubber in a marking shape, printed on the tire side, indicating that the tire is lightest at this point. When assembling, it should be facing the valve to ensure the balance of the entire tire.

Rolling direction: The pattern on the tire is particularly crucial for drainage and anti slip during driving, so off-road vehicle tires with asymmetrical patterns often use arrow markings to assemble the rolling direction to ensure the designed adhesion, anti slip and other performance. If installed incorrectly, it will have the opposite effect.

Wear limit mark: One side of the tire is marked with a rubber strip or block to indicate the wear limit of the tire. Once the tire reaches this mark position, it should be replaced in a timely manner, otherwise the tire may burst midway due to insufficient strength.

Production batch number: Use a set of numbers and letters to indicate the manufacturing year, month, and quantity of the tire. For example, “98N08B5820” refers to the 5820th tire produced by Group B in August 1998. The production batch number is used to identify the condition and storage time of tires.

Trademark: A trademark is the logo of a tire manufacturer, including trademark text and patterns, which are generally prominent and eye-catching, and easy to recognize. Most of them are linked to the name of the production enterprise for identification.

Other markings: such as product grade, production license number, and other associated markings. Can be used as a reference material and information for selection.

The role of tire patterns

The effect on drainage: Directional tire patterns can enhance drainage performance. In addition, the asymmetric “rib” pattern also has excellent drainage performance. The pattern design of longitudinal and transverse grooves can ensure four-way drainage, improve drainage performance, and make wetland braking and handling excellent.

Beneficial for reducing tire noise: Specific tire patterns can greatly reduce driving noise and ensure a quiet interior during high-speed driving. If car owners pursue a quiet driving environment, variable frequency flower block design tire patterns can bring comfort and quiet enjoyment to their driving. In addition, some tire shoulder flower blocks adopt optimized audio design, which can effectively reduce noise during driving. Embedding high-efficiency vibration absorbing pad on the inner side of the shoulder tire has the function of noise reduction and shock absorption, reducing road noise caused by road vibrations.

Conventional tire classification

There are many standards for tire classification, commonly based on inflation pressure, tread pattern, tire structure, and purpose.

Classified by inflation pressure: ① High pressure tires: Inflation pressure is generally above 5.5 kilograms per square centimeter, with high stiffness and poor cushioning performance, and are rarely used; ② Low pressure tires: The inflation pressure is generally 2-5.5 kilograms per square centimeter. With the improvement of cord strength and tire bearing capacity, some tires have an inflation pressure exceeding 5.5 kgf/square centimeter, but their cushioning performance is similar to that of low-pressure tires, still classified as low-pressure tires; ③ Ultra low pressure tires: The inflation pressure is generally less than 2 kilograms per square centimeter.

According to the tread pattern, it can be divided into: ① Regular pattern tires: there are many styles that combine longitudinal, transverse, and both directions. Ordinary transverse tread tires are suitable for use on poor and gravel roads; Longitudinal patterned tires are suitable for use on better road surfaces; Tires with both longitudinal and transverse patterns are suitable for use on both general and poor road surfaces Off road patterned tires: The tread has large patterns, suitable for use in mines, construction sites, deserts, loose soil, and snowy roads Mixed pattern tires: suitable for both good road surfaces and gravel and loose soil roads.

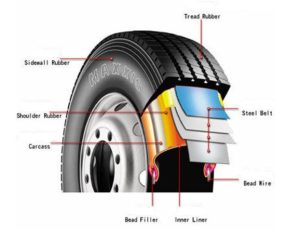

According to the structure of the tire body, it can be divided into: ① ordinary structure tires: the cords of the ply are laminated and bonded in a cross form, the tire body is sturdy, has good lateral rigidity, but poor cushioning performance. ② Radial structure tire: The cord of the tire body is arranged in a radial form, orthogonal to the circumference of the outer tire, and the strength is fully utilized. Radial structured tires have lower rolling resistance, better cushioning performance, and longer driving range than regular structured tires.

According to usage, it can be divided into passenger tires and heavy-duty tires: ① Passenger tires: low-pressure tires with an inflation pressure of less than 4 kgf/square centimeter, generally with 4-6 ply cords and a tire bead diameter of less than 16 inches. Passenger tires are used for cars and light trucks, and passenger tires are developing towards ultra-low pressure Load bearing tire: A low-pressure tire with an inflation pressure of 4 kilograms per square centimeter or more, typically consisting of 10-16 ply cords and a bead diameter of 16-32 inches. Load bearing tires are used for medium and heavy-duty trucks, buses, and trams.